Spajic® steel fibers

We present Spajic® steel fibers, an innovative solution for concrete reinforcement that offers numerous advantages over traditional methods. Spajic® steel fibers are made from cold-drawn wire selected for specific applications. They are designed to prevent concrete cracking, increase flexibility, improve shear resistance, and enhance wear resistance.

SPAJIC® steel fibers

We present Spajic® steel fibers, an innovative solution for concrete reinforcement that offers numerous advantages over traditional methods. Spajic® steel fibers are made from cold-drawn wire selected for specific applications. They are designed to prevent concrete cracking, increase flexibility, improve shear resistance, and enhance wear resistance.

Our Products

Explore Our Range of High-Quality Reinforcement Fibers

MICROFIBERS

SA/ M,N, Z, I

↔ 3 – 30 MM

Ø 0,15 – 0.4 MM

HOOK ENDED

ZS/N, M, Z, I

↔ 30; 35; 40; 50; 52; 60 MM

Ø 0,4 – 1,2 MM

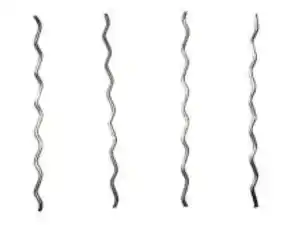

CORRUGATED

ZSW/ N,M, Z, I

↔ 20 – 65 MM

Ø 0,6 – 1,2 MM

ZS/5

ZS5/ N, M, Z, I

↔ 50; 60 MM

Ø 0,6 – 1,2 MM

Features and benefits

Increased crack resistance and toughness

Steel fibers significantly increase concrete’s resistance to cracking, enhancing its energy absorption capacity and toughness. This contributes to the durability and stability of structures..

Improved resistance to impact and fatigue

Steel fibers improve concrete’s resistance to impact and fatigue, making it more durable and long-lasting. These properties are particularly beneficial in demanding conditions where concrete is subjected to intense loads.

Increased load-bearing capacity and reduced cracking

High tensile strength fibers bridge joints and cracks in concrete, resulting in a stronger and more stable structure. This increases the load-bearing capacity of the concrete, making it more reliable for heavy constructions.

More efficient installation and cost reduction

Installing steel fibers in concrete requires less labor and time compared to conventional reinforcement. This reduces labor costs and speeds up the construction process, making it more economical.

https://spajic.com/wp-content/uploads/2024/06/ApplicationVLaknaSPAJIC.mp4